Rapid Construction

Powered by 3D Printing & Eco Friendly Additives

Our Technology:

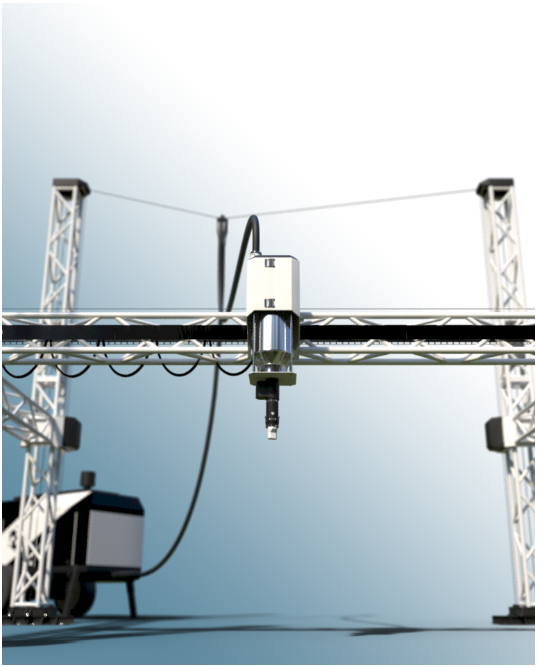

Applied Nanotek 3D printers have a print area from 6x4x3 to 12x16x8 meters and can work around the clock. The equipment is serviced by a two-person shift – a printer operator and a mixture preparation specialist. The construction of the building box, according to our or adapted project, is carried out at a speed of more than 500 mm per day.

Printer Manufacture

Development and production of large-scale 3D printers. We make printers with print areas up to 12x16x8 meters.

3D Printed Construction

Printed houses and fixed form work, large structural elements, small architectural forms from concrete mixtures.

Design

Development of architectural solutions for additive technologies. Adaptation and recalculation of existing projects.

Equipment

Assembly, adjustment and testing of equipment on site are carried out within 1-2 days, depending on the transport accessibility of the facility.

Large-format 3D printer for buildings on foundations 12x16m. Can also print small architectural forms and infrastructure elements. It has a modular design and is customizable to increase the print area up to 12x100m.

The complete printer set can be expanded to include a high-pressure washer and a synchronized mortar mixture supply station. The basic package includes a control computer with pre-installed software. The printer works with base building mixes of grades 400-500 and can use mixes with graphene and mineral additives.

Blends for printing.

The composition of our mixtures allows printing in a wide range of temperatures and weather conditions, without loss of properties during polymerization.

Printing in difficult conditions.

Our printers can prepare the site for printing “from the ground”. This is used for printing pile foundation grillages. And ensures accurate laying of subsequent layers.

Print area:

Length: 15.5 m

Minimum length 3.5m.

Width: 11.5 m

Minimum width 3.5m.

Height: 7.0 m

Minimum height 3.0 m.

Speed: Travel speed: 350 mm/s

Maximum speed on straight sections.

Positioning speed: 500 mm/s

Maximum speed on straight sections.

Z-axis travel speed: 25 mm/s

Maximum positioning speed.

Printer dimensions:

Length: 16.2m

Minimum length 4.2m

Width: 12.2m

Minimum width 4.2m

Height: 8.2m

The minimum height is 4.5m.

Other: Positioning 1-2 mm

The minimum height is 4.5m.

layer height: 5-35mm

depending on the mixture.

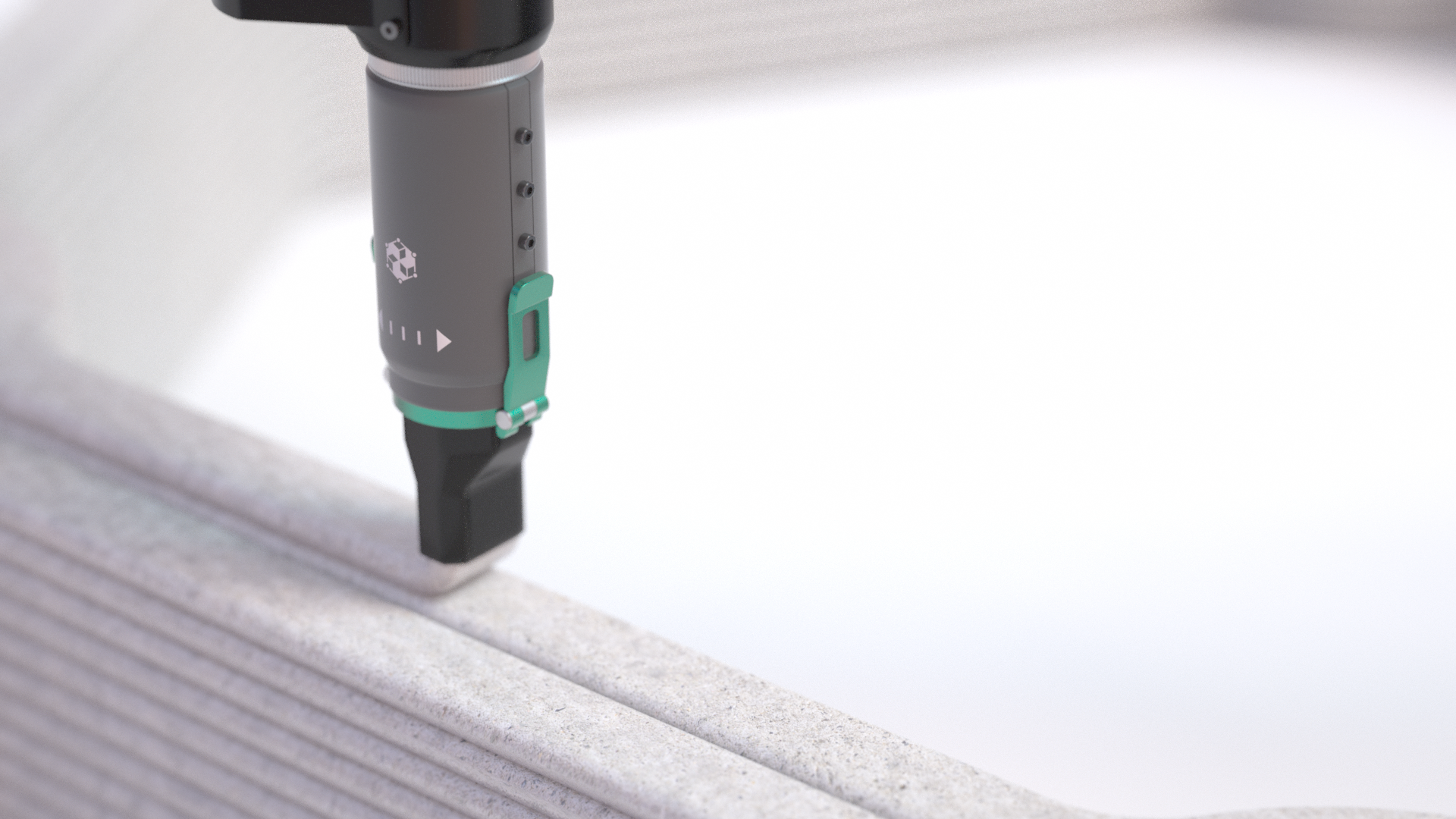

Nozzle diameter: 20-50 mm

Printed line width + 5-7mm

Compatible materials:

Sand concrete, foam concrete, gypsum concrete, fiber-reinforced concrete.

System Overview:

Printer. Tablet or laptop. System disk image (everything necessary Software is pre-installed on the equipment. Control unit. Passport. User manual (in the customer’s language). A set of nozzles, including an STL file, for making additional nozzles.

Additional System Modifications:

Durable hose. High pressure washer. Video surveillance system. Climate control of the control unit for regions with difficult climatic conditions.

FAQ:

What are the advantages of 3D printing over traditional construction technologies?

The process of building houses using 3D printing is several times faster compared to traditional building technologies.

The “human factor” is minimized. Lower construction costs by lowering labor costs.

How many floors can I print with your printer?

The printing height is 8 m, which allows the construction of two-story and three-story buildings.

Can I use your foundation printing equipment?

Fixed formwork printed on our printer withstands concrete pouring, and can be used to create grillages.

What else can be printed on a construction 3D printer?

In addition to fixed formwork, it is possible to print building blocks, gazebos, pool walls, and landscape design elements.

What is the construction speed?

The speed of construction depends on several factors, such as weather conditions, availability of materials and the complexity of the architectural solution. The usual speed is a set of 300mm of height per shift.

How to prepare a building model for printing?

The building is a complex architectural structure, all calculations must be made by specialists. If the modules and formwork are calculated, they can be built in a 3D editor, and then g-code prepared in any of the slicers, in accordance with the printer settings.